Reverse engineering

Reverse engineering (reverse design) of assemblies, products, mechanisms is one of the activity areas of our company.

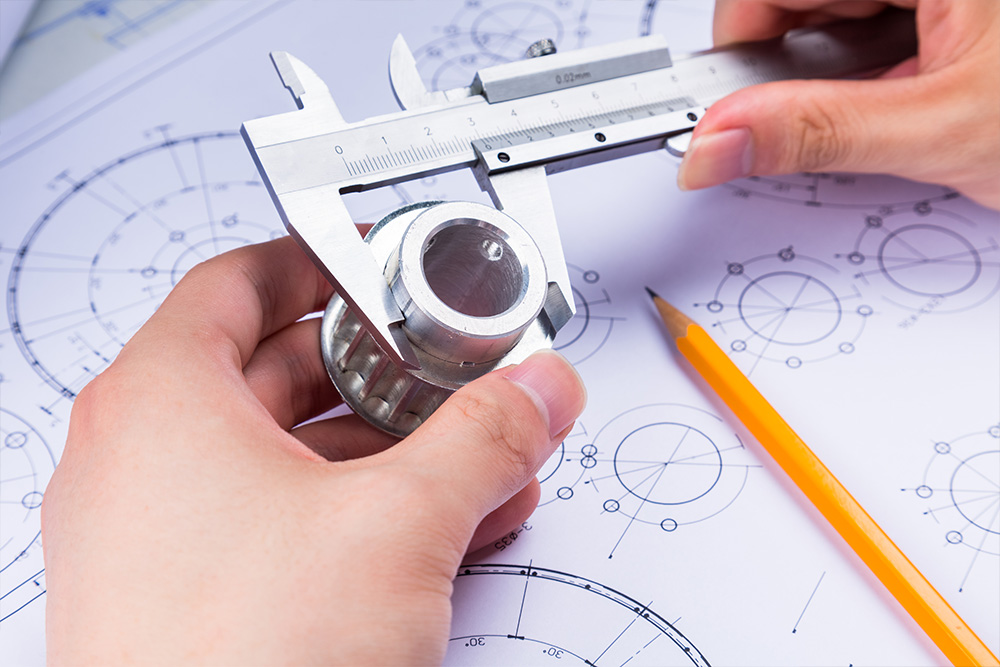

Reverse engineering is the process of copying (recreation) of a product using a finished specimen. The reverse engineering process presupposes recreation of design and process documentation according to which a similar product can be made in future.

It should be noted that one must differentiate between reverse engineering of products and the making of drawings according to a product specimen.

Reverse engineering of a part is the taking of dimensions with measuring tools or 3D‑scanning, creation of a 3D model and development of drawings on its basis.

Product reverse engineering is a creative process which requires, in addition to reverse of all the product parts, also the understanding of the production technologies, mechanism operation principles, use of design experience which allows for joining all the mechanism parts so as to achieve the specified production operation characteristics.

Reverse engineering is a complex process, and we consider each project individually, both from the viewpoint of expediency of copying and from the viewpoint of product DD development.

High-quality and quick reproduction of a complex product using a specimen requires a good technical assignment, comprehensive initial data, availability of the product itself and, of course, a specialist who knows its operation technology.