Cost of the 3d scanning service depends on several factors:

- requirements to the final result,

- complexity of the object for scanning,

- need for rework of the 3d model,

- urgency and conditions of works,

- need for a visit with the scanner to the customer’s territory.

|

Works |

Description |

Cost |

|

3d scanning with processing, parts of simple configuration. Format: STL

|

Simple configuration: a part without sharp edges, hard-to-reach cavities, large number of surfaces and small elements. Work scope: - object preparation for 3d scanning (cleaning, application of marks), - scanning and joining of point clouds to create a single grid, - correction of various defects in the grid. |

From 3000 roubles |

|

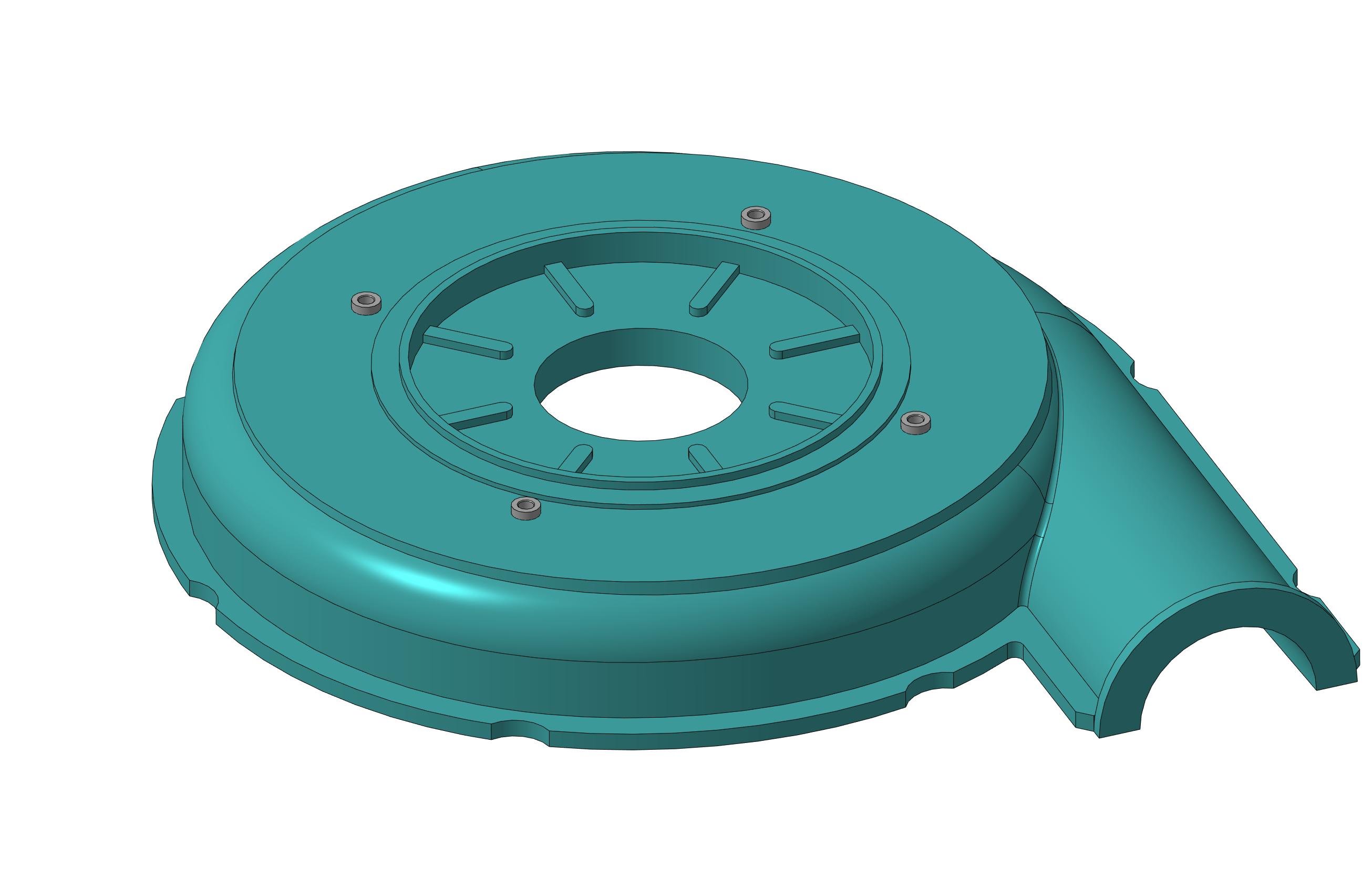

3d scanning with processing, parts of complex configuration. Format: STL

|

Complex configuration: a part with sharp edges / hard-to-reach cavities / with a large number of surfaces or small elements. Additional work scope: - rework of elements which are outside the scanning zone; - rework of the object geometry to the required parameters; - restoration of small clearances in the grid; - manual levelling of NURBS-surfaces. |

From 5000 roubles |

|

Solid CAD-model. Format: STEP, STP, IGES, X_T.

|

Additional work scope: building of a solid model in the CAD-format as a single body, without breakdown into sketches and operations (without a building tree). |

From 5000 roubles |

|

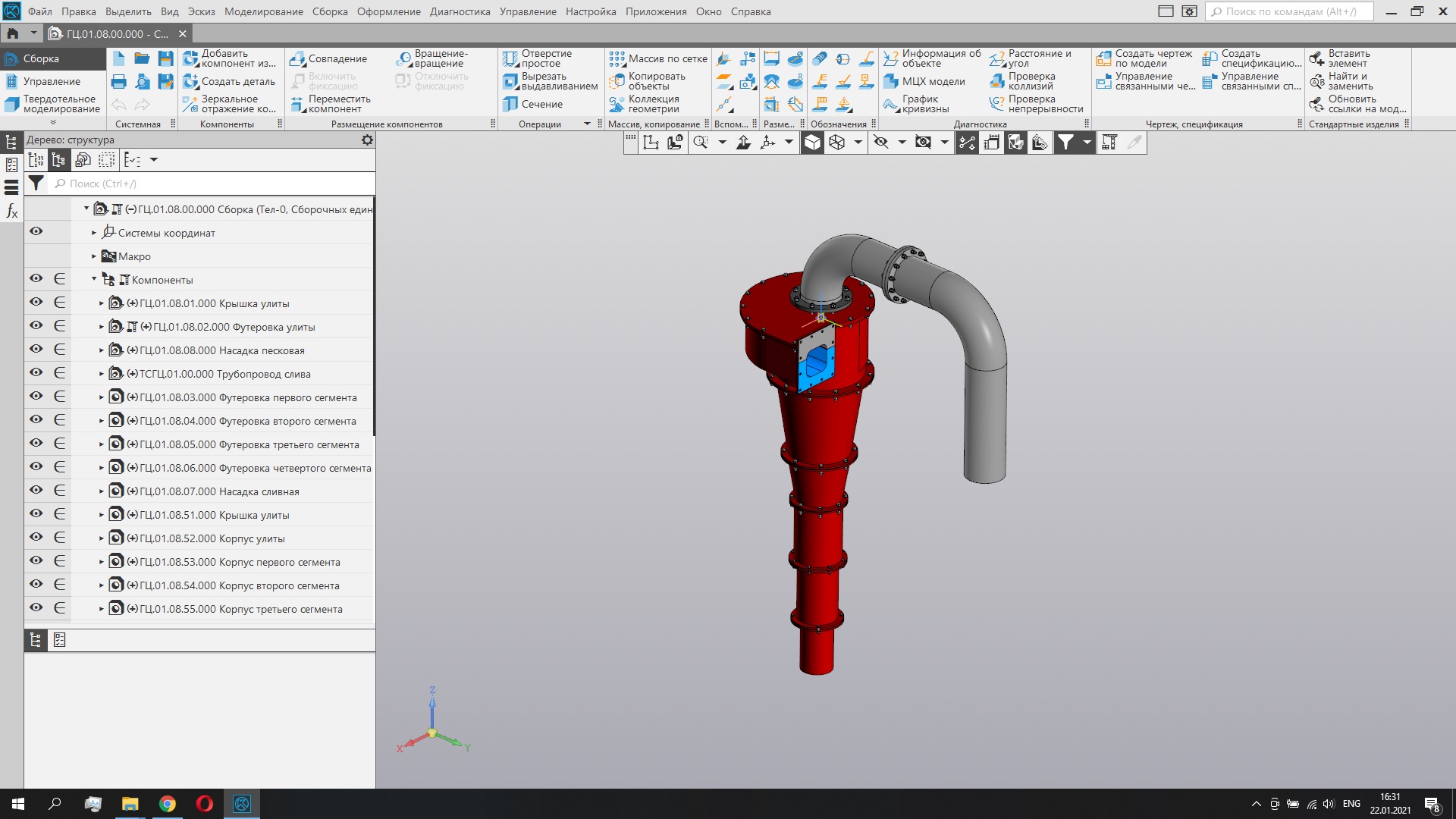

A solid CAD-model with a building tree Format: in the CAD-program format.

|

Additional work scope: building of an editable solid model in the CAD-format with breakdown into parts, with a building tree. |

From 7000 roubles |

|

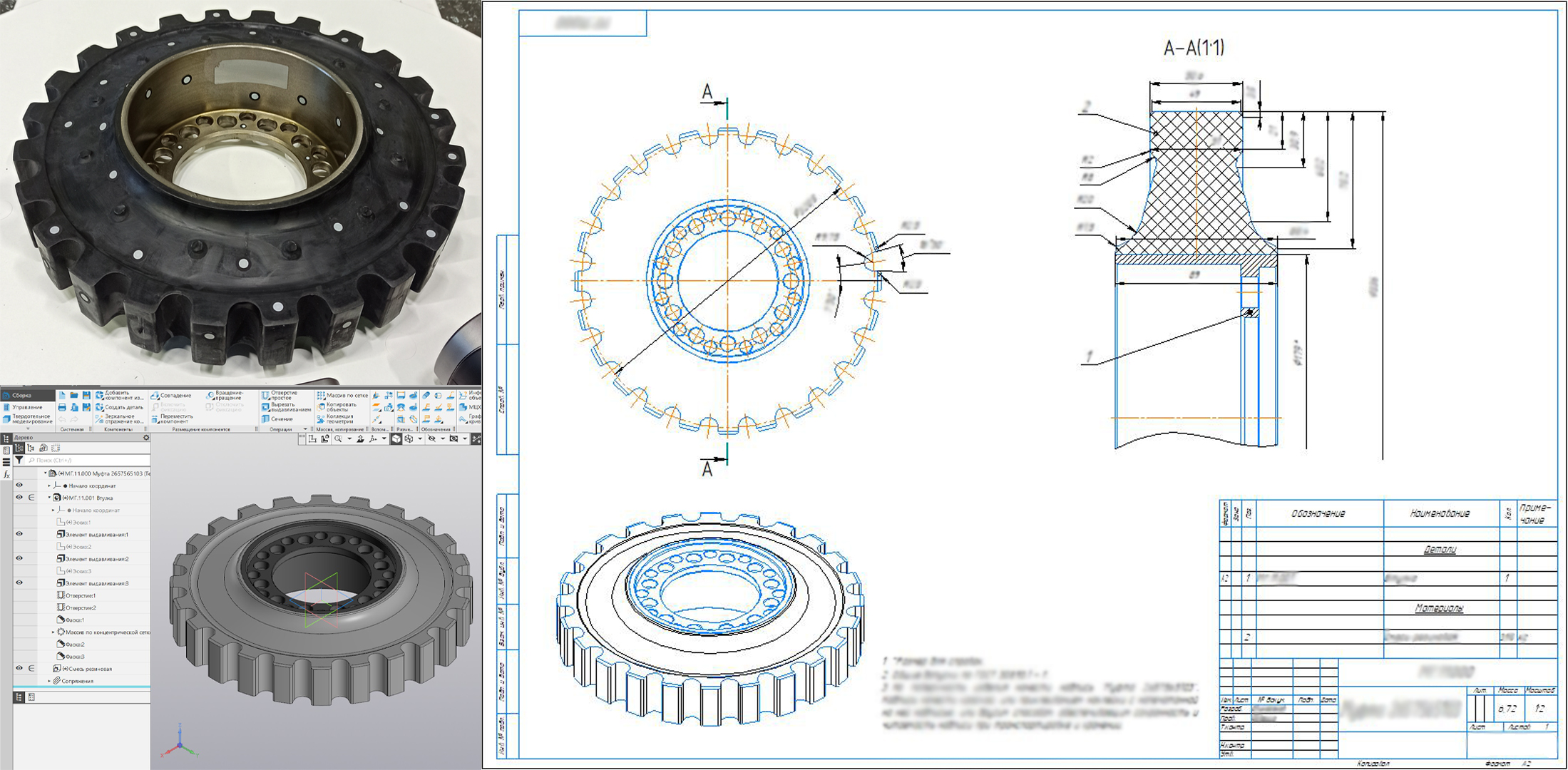

3d model with drawing. Drawing format: pdf or source in the CAD-program format for editing.

|

Additional work scope: development of a drawing with referencing to the model. |

+ 20-30% to model cost |

Size. The standard part sizes are those up to 35 cm.

When scanning larger parts, time for part preparation and quantity of necessary marks for scanning increase. In this case, the part must be scanned by parts and then be joined in the scanner software.

Moreover, scanning of large-size objects with a high accuracy and the minimum accumulative error requires the use of a photogrammetry system.

Weight. Standard scanning is scanning of part weighing up to 10 kg.

A part over 10 kg requires greater physical efforts during preparation for scanning and turnover during scanning.

A part over 50 kg requires special means for lifting/turnover (cargo crane, loader).

Part configuration and surface geometry.

Parts with hard-to-reach places are particularly complex for scanning. Hard-to-reach places are: deep holes with different internal diameters and threads, voids, bending parts etc. Such elements may be outside the scanner vision zone and will not be reflected in the scanned model. Dimensions in this case must be taken manually, and then the scanning results must be also manually reworked using software.

Additional time for processing of a scanned model will be required if the surface is porous or uneven (artefacts and voids formed during casting, or present welded seams).

Complex surface geometry (large number of curved surfaces, part elements) will not affect the scanning labour intensity, but will heavily affect the processing labour intensity, particularly when building a solid model.

Moreover, the drawing of such a part will also require more time than the drawing of a simple plain part.

There are also small parts, which do not seem complex at first sight, but the large number of dimensions (radii, holes, cut-outs etc.) makes the drawing preparation a labour-consuming task. For instance: a vane may look a simple part, but a lot of views and sections must be drawn to make a drawing of this part.

Need for rework of 3d model.

If it is necessary to restore broken or worn-out parts or if the customer has upgrade requests, building of a solid CAD-model with designer’s rework will be required.