Our specialists had to solve the task for creation of a 3D model “Coupling-compressor connection” and subsequent design and process documentation for production. For this, we performed 3D scanning of the original product, and then this data was used for development of a CAD model. Scanning was performed using manual (portable) laser 3D-scanner Scantech KScan20.

Figure 1 (Part for scanning)

One-time light-reflecting marks were applied on the part before scanning.

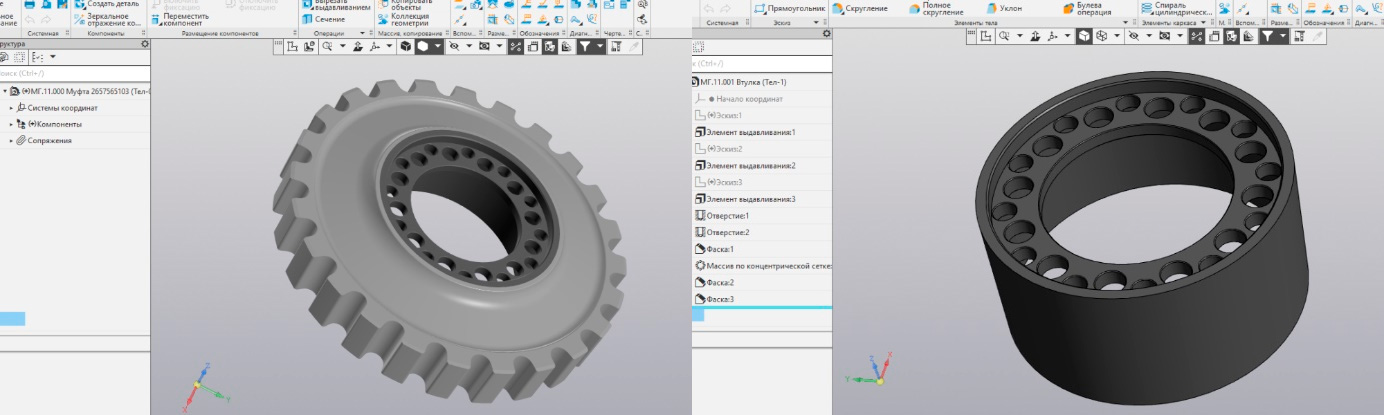

Figure 2 shows the product 3D models developed on the basis of the 3D scanning data.

Figure 2 (product CAD models)

Figure 2 (product CAD models)

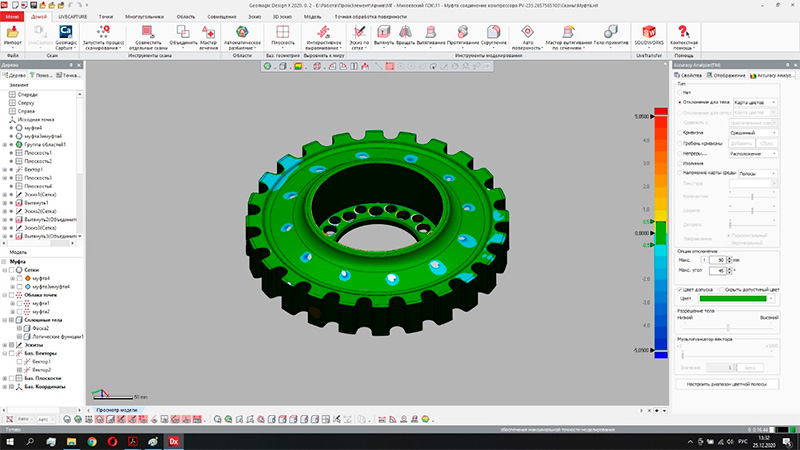

When building a 3D model of the coupling, geometric deviations of the built model from the scanning data were additionally analyzed. The analysis result allowed for making a conclusion on qualitative building. The developed process documentation was used to obtain the first product specimens and its batch production was started.

Figure 3 (Analysis of CAD model deviations from the product scanning results)